Advanced

Die Steel For Die Casting DAC-MAGIC

DAC. Standard grade for general use with good balance of

toughness, strength at elevated temperature and with excellent hardenability.

DAC-MAGIC. High performance die steel for die casting with

well-balanced strength and toughness and strength at elevated temperature.

DAC is most widely used as Die for Aluminium and Zinc

Diecasting. DAC is hot working

tool steel with good balance of strength, toughness and heat resistance.

With introduction of Isotoropy technology DAC has become tougher and more

isotropic to help life of dies longer and stable.

Overview

・The range

of applications of die cast products is expanding for weight saving and

recycling while awareness of environmental protection is increasing.

・This fact

requires bigger die cast products to be produced with higher quality in short

cycle.

・In order

to meet such needs, DAC-MAGIC is one of the best materials for die casting

which has not only good heat crack resistance but also good toughness.

Features

・High

strength at elevated temperature and excellent heat crack resistance

・High

toughness prevents gross crack of die

・Improved

stress corrosion cracking resistance reduces crack problem from cooling channel

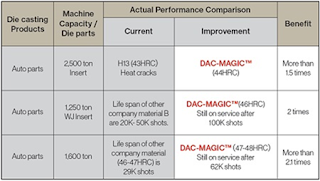

Comparison

with Current Materials

Characteristics

DAC-MAGIC™: Advanced die steel, good heat crack resistance and

good toughness.

DAC™10: Good erosion resistance.

Heat Crack Resistance

Compared with conventional

steels, DAC-MAGIC contributes to longer die life due to better heat

crack resistance.

Resistance to Stress Corrosion Cracking

DAC-MAGIC has excellent resistance to stress corrosion

cracking and suppresses cracking from cooling channel.

Application Example

Performance of DAC Magic

material in Cutting dies

The performance and life of the cutting dies has been

improved drastically, with the subsequent changes in tool material from D2 to

Dac magic. The above is highly appreciated working with the high thickness hot

rolled steel plates. You can feel the impact and vibrations of cutting load

produced during their processing, the resistance of the material against high compressive

loads is admirable, which in turn results in low wear and tear during the

process, eventually helps to reach the target of more cycles and improved wear

life of the dies.

Applications where DAC Magic has been tried out

In the below combination dies, where the cutting edges are

very close, leaving only margin of single sheet thickness, which is 9mm thick

hot rolled material. The skin of hot rolled materials are usually harder

compared to the core, resulting in more tool wear and tend to stick to the

punches after certain abrasive wear on the surface.

The lifespan of D2 material was just 5000~10000 strokes, whereas the life of DAC material has been found to be 30000~50000 strokes, provided the latter to be used with only Vacuum heat treatment.

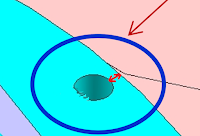

Apart from the above, it can be used where there are sharp

radius or sharp profiles on the closed corners of the cutting dies, results in

stress concentration and prone to early life cracks. For instance, in the

trailing picture, the marked edge of the die is exposed to more stress

concentration compared to the other areas, will eventually cracked from here

only.

Combined to the stress concentration, heavy sheet thickness

also induces more vibrations and repeated cyclic loads, needs for the right

blend of toughness, hardness and right blend of compressive strength. The right

choice of material along with optimized heat treatment process in combination

with the proper die design may enhance the die life up to 10X times.

Whereas the cost of the material and heat treatment process is much lower than the benefits drawn from the reduced frequent breakdowns and reduced product cycle times along with other indirect small benefits such as labour/machine utilization, reduced spare part inventories, low manpower for die maintenance etc.

SOME MORE HELPFUL TOPICS :

Bending Force Calculation

Forming Limit Diagram

Sheet Metal blank size calculation

Lean Manufacturing Terminologies

Brief Comparison of Hydraulic and Mechanical press

TECHNICAL TERMINOLOGY OF WHEEL TIRE

Raw material calculation of Complex Deep drawn Geometry

Modify the product to make it aesthetically better and more cost effective

How creativity results in major cost savings

How concrete analysis resolve warranty issues

Proud of being Granted with your first patent

How hastened decisions affect the business in the long term

How cost reduction is the key factor to capture the market share

How to choose number of Draw process for deep drawn geometry

Essential parts of a draw die

Electric vehicle (EV) – Future of Transport

Surface coatings to increase the tool wear life

HYDRAULIC PRESS - BRIEF TERMINOLOGY

0 Comments