Benefits of Forming simulation

Forming simulation has been proved most valuable high tech tools introduced in the past decade and is special type of finite element analysis (FEA) that simulates metal deformation along with possible defects may occurs during the process.

One of the biggest uses of the technology in sheet metal industries, where forming of critical shapes is head-ache for the tool designers and tool makers. The simulation package or program so called software uses two types of forming methods :

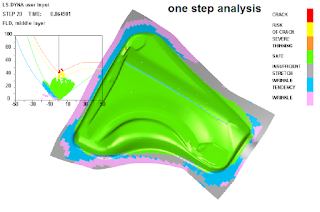

1. One step simulation

2. Incremental simulation

Benefits of One step forming simulations:

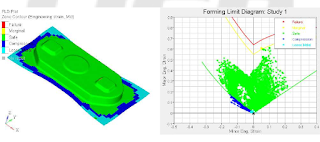

Quick feasibility : One step solver is an easy way to predict the manufacturing feasibility of the geometry in product design stage with FLD plots, thinning and areas of failure. One good book is highly recommended to learn about the method is ''Practical guide to forming simulation'' by Rakesh kumar. Even though there are many books on the topic, shed light only on theory, but nobody tell you how to exactly do that. This book contains the right blend of both theory and practical in very clear and effective manner.

Material size calculation :

Robust product design:

Once you learn the one step set up, it will allow you to pass your design in the series of iterations. Product is easy to amend in the design stage rather than the costly ECN in the later stages of life cycle. Weak product design has to be paid in the long run, in terms of money loss, time loss and most important brand image loss. Therefore proper analysis and correction in the design stage would lots of efforts in the later stages and provide competitive edge in the market.

Benefits of Incremental forming simulation:

This setup is specifically for process/die designers for accurate work and arresting possible defects before making physical dies, which saves enormous amount of time in terms of money, which otherwise should have wasted on the costly iterations and time consumed in number of die trials. As a result, product development cycle squeezed. The same book as mentioned above is highly recommended to learn and use the terminologies in details.

Proper process layout:

By learning this set up you can choose the most easy route/process to make the final product, the process designs are easily validated in the design stage. The most value able time and money can be saved, which otherwise should have been wasted in rectifying the dies after each trials.

Boost the confidence:

Once you have learn to set up the virtual process and implemented in 3 or 4 products, your confidence will automatically arise and your process will get refined.

Right input leads to right output:

The above book reading is highly recommended before using the software, even if you have learned it from somewhere. The most tutor will explain you the necessary things and leave the most important inputs, which otherwise can spoil your results.

The inputs such as mechanical properties like n-value, r-value, yield strength, young's modulus, poisson ratio, density, lankford coefficient etc. are utmost important.

The book will facilitate you to understand the terms first before using it, leads you to the more accurate results.

If you want to learn the Metal forming simulation, read the book "Practical guide to forming simulation"

Or

Buy from here at 20% discount.

Or

Or

Buy the book from Notion press

Or

Or

Or

Or

Or

0 Comments