Bending Force Calculation :

There are various ways to calculate the bending force of a sheet metal parts, most basic is to use the formula. Since it's a basic and everyone should know about theory, however there may be some variations in results due to error in input values such as Tensile strength, coeff. of friction (not considered in formulas), press type (Mechanical or hydraulic) and other practical aspects which are not possible to measure. Therefore these force values to be taken as reference and sufficient factor of safety to be considered, minimum 20% to be added to select the final press. 100% correlation of formula and actual press force is impossible, even FEA softwares have certain limitations.

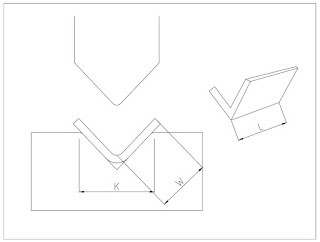

Bending in a V-die with rectangular cross-section:

versa). A 1.33 value is used for a die opening of 8 times metal thickness.

W = width of the bent-up portion

L = distance between material supports

S = ultimate tensile strength

For instance, Let's assume a sheet part with thickness 3mm, Kv =2.5, more than 8x of thk., L=60, W=75, S=41

Force = (2.5 x 41 x 75 x 3 x 3) / 60 ⇒ 1153 Kgf

To check the accuracy of the formula, the co-relation has been made with the FEA force calculation :

FEA force is 10231N = 1044 kfg (almost nearby the formula)

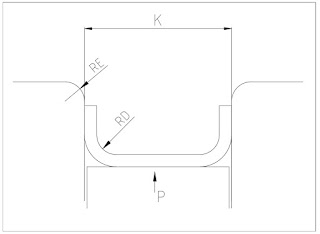

Bending in a U-die, equipped with a spring-loaded pressure pad:

where kU = die opening factor, 0.4 to 10

RE = radius, die edge (see Fig. 8-53)

RD = radius, bottom of U channel

Ppad = pressure of spring-loaded support

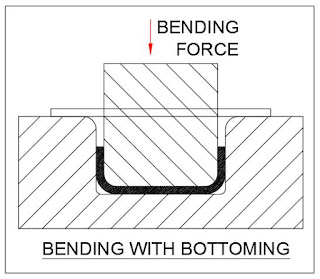

Bending with bottoming (coining):

Bottoming force (F) = A X S

where S = Tensile strength

A = area of part, subjected to coining

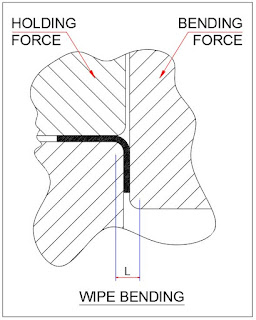

Wipe bending dies pressure calculation:

where L = distance between supports of the material

W = width of the bent-up portion

S = ultimate tensile strength

t - Sheet Thickness

FORCE CALCULATION IN ROTARY BENDING

F = 2.25 x S x (PL x t / L)

PL = width of the bent-up portion

S = ultimate tensile strength

t - Sheet Thickness

If you want to learn the Metal forming simulation, read the book "Practical guide to forming simulation"

The book is available via. the following links.

Or

Buy from here at 20% discount.

Or

Or

Buy the book from Notion press

Or

Or

Or

Or

Or

SOME MORE HELPFUL TOPICS :

Bending Force Calculation

Forming Limit Diagram

Sheet Metal blank size calculation

Lean Manufacturing Terminologies

Brief Comparison of Hydraulic and Mechanical press

TECHNICAL TERMINOLOGY OF WHEEL TIRE

Raw material calculation of Complex Deep drawn Geometry

Modify the product to make it aesthetically better and more cost effective

How creativity results in major cost savings

How concrete analysis resolve warranty issues

Proud of being Granted with your first patent

How hastened decisions affect the business in the long term

How cost reduction is the key factor to capture the market share

How to choose number of Draw process for deep drawn geometry

Essential parts of a draw die

Everything about patent

sheet metal processing and latest trends

Electric vehicle (EV) – Future of Transport

0 Comments